Mark Paul, Global Director of Sales at IRISS, suppliers of the Safe-Connect range of thermochromic indicators, looks at why the use of colour change technology can help to keep electrical systems and operatives safe and sound.

Picture this: you’ve just completed an inspection at a bustling site. Everything appears to be in good working order. But beneath the surface, trouble could be brewing – a cable running hotter than it should, a terminal on the verge of failure, or a connection slowly degrading under stress. These overtemperature risks are invisible to the naked eye, lying dormant until they erupt into costly failures, unexpected downtime, or even dangerous accidents.

For electricians, this scenario is all too familiar. But what if there were a simple way to make these invisible threats impossible to miss?

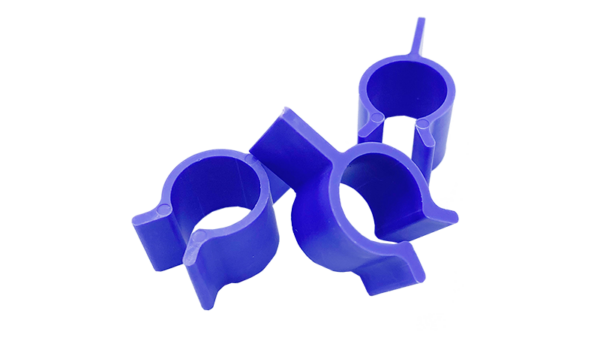

That’s precisely what thermochromic overtemperature indicators offer. These innovative devices – available as clips, labels, and wraps – are applied directly to electrical equipment such as cables, terminals, and connections.

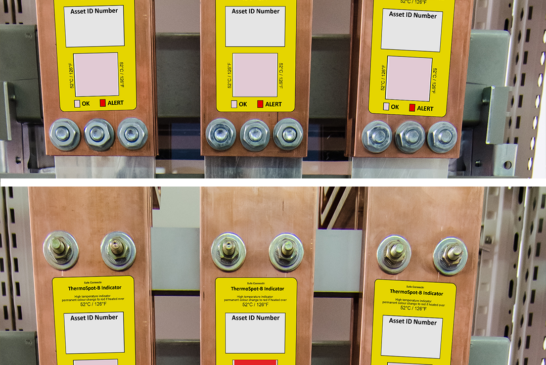

When the temperature exceeds a critical threshold, the material undergoes a permanent colour change – in the case of Thermo Clips, shifting from purple to pink. This stark visual transformation provides an immediate and unmistakable warning of overheating.

Even after the equipment cools, the colour remains permanently altered, serving as a lasting record of the event. No advanced tools or technical training are needed; a quick glance is all it takes to pinpoint the problem area.

How does it work?

The magic of thermochromic indicators lies in their unique chemical composition. The molecular structure of the thermochromic material alters when it reaches a specific temperature threshold, which in turn changes the wavelengths of light it absorbs and reflects. This results in a vivid and permanent colour shift, making the problem areas stand out immediately.

Unlike digital monitoring systems, thermochromic indicators require no external power source, wiring, or complex setup. They operate passively, relying solely on temperature changes to trigger their colour shift. This makes them incredibly reliable and easy to install.

Whether you’re working with high- voltage switchgear or low-voltage distribution boards, these indicators can be deployed in seconds, providing continuous monitoring without the need for periodic recalibration or maintenance.

Filling the gaps in routine inspections

While infrared (IR) thermography and other diagnostic tools remain essential for electrical system inspections, their effectiveness is inherently limited by their periodic nature.

IR inspections offer a valuable snapshot of an asset’s condition but only capture data at the moment of the inspection. Between these scheduled checks, transient or intermittent overtemperature events often go unnoticed, leaving systems vulnerable to undetected risks.

Thermochromic indicators bridge this gap by providing round-the-clock monitoring. Their passive, always-on nature means that they’re constantly watching for temperature anomalies, ready to alert you the moment a threshold is breached. This complements traditional inspection methods, adding an additional layer of safety and reliability to your maintenance routine.

Many electrical system applications

Thermochromic overtemperature indicators can be applied to virtually any electrical system component:

Cables and connectors

These are often the first points of failure in an overtemperature event, especially in high-current applications. Thermo Clips and Thermo Wraps provide a simple way to monitor these critical areas.

Transformers and motors

Continuous operation under heavy loads can lead to dangerous overheating. Thermochromic labels or Thermo Paint applied to these components offer a clear, visual warning before damage occurs.

Control panels and enclosures

In busy industrial environments, overheating within control panels can lead to costly malfunctions. External thermochromic indicators make it easy for operators to identify any hotspots without making physical contact.

Busbars and terminals

These critical junction points are prone to thermal stress, especially in ageing systems. Thermochromic indicators applied here provide early warnings, giving you plenty of time to address the issue and reduce the risk of failure or fire.

Empowering everyone on-site

One of the standout features of thermochromic indicators is their accessibility. Unlike diagnostic tools like IR and ultrasound, which require specialised training to operate and interpret the results, thermochromic indicators are simple to understand.

A shift in colour is a universal warning sign, easily recognisable by any team member, no matter how experienced. This simplification of overtemperature monitoring means more eyes on potential issues and faster responses to emerging problems.

By turning routine walk-throughs into effective monitoring activities, thermochromic indicators foster a culture of proactive maintenance. Operators can spot potential problems during their daily rounds, prompting immediate investigation and preventing minor issues from escalating into major failures.

Safety, reliability… and sustainability?

In addition to improving safety and reliability, thermochromic indicators align perfectly with modern sustainability goals. Their passive operation means they consume no power, contributing to reduced energy usage across the facility. They detect overtemperature events from loose connections, reducing energy wastage. Moreover, their durability ensures they remain effective for years, minimising waste and the need for replacements.

By preventing equipment failures and unplanned downtime, thermochromic indicators also reduce the environmental and financial costs associated with emergency repairs and extended outages. In a world increasingly focused on sustainable practices, electricians are embracing the fact that these indicators provide a practical, low-impact solution for enhancing industrial safety and efficiency.

A game-changer for electricians

For electricians, thermochromic overtemperature indicators represent a eap forward in electrical system maintenance. They’re simple, effective, and affordable, offering a practical way to detect hidden risks before they escalate.

Whether you’re responsible for maintaining critical infrastructure or managing the day-to-day operations of an industrial site, these indicators empower you to stay ahead of potential failures with just your eyes.

Think of them as an early warning system that never sleeps. By making overtemperature risks visible and impossible to ignore, thermochromic indicators help you improve safety, reduce downtime, and enhance the reliability of your electrical systems.

In an industry where time is money and safety is paramount, this technology is poised to become an indispensable part of every electrician’s toolkit.

Get more details on the Safe-Connect range of thermochromic indicators, available from IRISS, here

Find more industry feature articles here