In this second part of our recent interview with Philip Grove, Circuit Protection Product Manager at Luceco, we learn more about bidirectional RCBOs, the legislation driving such changes and the training on offer.

After Philip discussed some of the recent trends and developments in circuit protection last month, its important now to look at recent legislation changes that specify the use of bidirectional RCBOs in prosumer installations and the ways that brands like Luceco are helping electricians and contractors to navigate these challenges.

He says: “I believe the industry is still in the process of coming to terms with the changes that were introduced with AMD 3 that was published in July 2024. It’s been really interesting to see that there’s still a mixture of devices out there – being Unidirectional or Bidirectional doesn’t always correlate with them being single and double pole retrospective.

“In short, unidirectional means you can draw power out, whereas bidirectional means you have the ability to draw and feed power back in the circuit protection device without compromising on the safety or operation.”

Issues with identifying devices

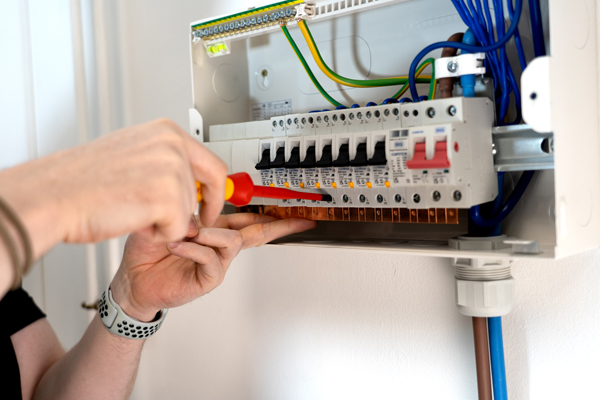

Despite the industry guidance, there is clearly still a disconnect in the eyes of some when it comes to identifying single-pole, double-pole, bidirectional and unidirectional devices, and this is something that Philip is keen to simplify for the installer.

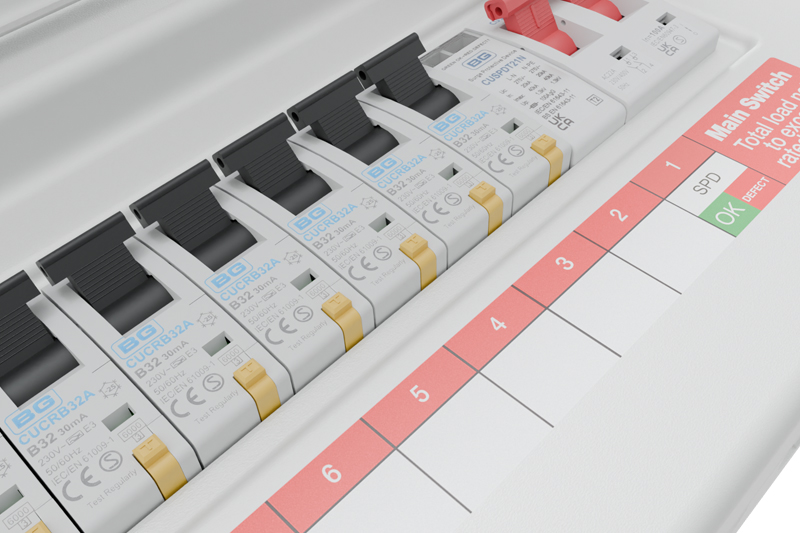

He explains: “From a Luceco perspective, we’ve decided to clear this up for all of our BG circuit protection devices. They are a clearly marked and identified with the appropriate markings. If it’s unidirectional, we’ll clearly mark the device with ‘in’ and ‘out’ terminals, and if it’s bidirectional we’ll primarily mark it was markings that do not reflect a current directional identifier. “Furthermore, in all our EV charge point offerings, every circuit protection device installed inside our enclosures is bidirectional – whether it’s our RCDs, MCBs or RCBO devices. Again, this is because the owner of an electric vehicle and charger needs to have the capability of feeding power through the protection circuit without compromising on its safety. It’s a protocol that we rolled out in the middle of last year to make it standard on all of our EV charging products.”

One element that is always key when informing and educating industry professionals on legislation changes is the provision for technical support and training.

Fortunately, Luceco has its finger firmly on the pulse in this area, as Philip explains: “One element that we believe sets us apart as a brand is the technical expertise we have in-house to support our customers.

We have a dedicated team available five days a week who will cover all aspects of technical support – from retail queries and warranty issues, right through to technical installations or setups with contractors. “We think it’s really important to have a dedicated technical team in place, and one that gives us the information back very quickly so we can react and make important decisions when it comes to product development. If we need to bring in an industry expert from our own team, we have the ability to do that.”

Philip continues: “In addition to the technical support team, we’re also really big on proactive training and have a whole mix of training offerings for professionals to take advantage of. This includes CPD-accredited training, delivered by our experts who sit on our working committees.

“This is essential when training installers, contractors and trade counter staff. We can also deliver training through our other industry partners, such as NAPIT and eFIXX, which feeds into our academy and is available for any individual to make use of.”

So, with the legislative changes that have taken place recently, what advice would Philip have to contractors who may be faced with prosumer installations in the future?

He answers: “There are two bits of advice that I’d give: a) you should always take into account beforehand what work needs to be undertaken for the installation and ensure you’re prepared, and b) make sure you’re working with products you have confidence in and that you can trust, knowing there is support available if needed.

“You want to make sure that you have a level of confidence in what you’re installing and are working with a brand that is diligent and thorough, going through the correct standards and legislation and is reputable. Installations are becoming more complex and advanced so having trusted products helps that little bit more.”

An accelerating trend

Moving forwards, it’s clear that the UK’s commitment to net-zero targets is going to have a significant effect on the adoption of prosumer concepts and applications, with Philip believing that the current trend will only accelerate in the coming years.

He says: “The prosumer conversation is massive at the moment and the wheel has started to turn to the extent where more people are adopting things like electric vehicles. In turn, they’re also looking at the cost of running these vehicles and the cheaper tariff that is available in the early hours to give them power and a more cost-effective way of running the vehicle, so there is a lot of shift there currently.

“At the same time people are looking at the standard rise of energy costs and they’re starting to give real consideration to other renewables like solar PV. This shift from solely consuming power to actually producing our own is increasing, and will eventually facilitate the removal of fossil fuels within the home from being used.

“The good news for our industry is that electrification, and the skills of electrical professionals, will be required to drive this. It’s also important that manufacturers are reacting to this as well with the size of consumer units increasing.

“From our side, we’re bringing out bigger and better offerings and devices are not only aligned to the current market demand, but are also future-proofed at the same time.”

Philip continues: “What I find really interesting is the push by households to reduce power consumption and improve energy efficiency, yet the size of consumer units and the number of ways and circuits we’re adding to properties is almost the opposite.

“At Luceco, we’re catering to this demand by bringing out double-row enclosures that give the provision for more ways and offerings. If you look at an average 3 or 4 bed house and turn back the clock 10 years, you’ll be using 10-14 modules at the absolute max. Now you’re dealing with anything up to 48 module size – so it’s a significant change.”

Final thoughts

So, does Philip have any final messages for readers? “I’m always really keen to highlight some of the ways that we do things differently to others, especially when it comes to the design, development and manufacture of products. We have our own manufacturing base which allows us to control quality and cost and to be in a situation where we can deliver solutions to market faster, so that’s a real benefit.

“All of our consumer units are coming out of our Telford factory designed, developed, engineered and built by us. Every one of them is also tested by ourselves, so you have that reassurance and peace of mind that when you’re getting a product, you’re getting a true BG product.”

Get more details about the BG range of circuit protection solutions here

Find more industry feature articles here