We learn more about the road ROBUS is taking to help improve the circular economy.

As the saying goes: ‘what goes around comes around.’ And when thinking about a circular economy, this saying fits perfectly.

A ‘circular economy’ operates on the principle of restoration and regeneration by design. It is driven by a need to transition to more renewable energy and materials. As the earth has a finite amount of resources, the aim is to create and develop practices that enable us to develop products that reduce the reliance on these resources and instead optimise product life cycles.

To understand the necessity for a circular economy, we must first look at our current state – a linear economy. In a linear economy system, we take materials from the earth, make products, and eventually throw them away as waste when we no longer need them.

In a circular economy, the opposite is true. We use less raw materials, design products for long life and recyclability, we share products, we use them for longer and repair things before we recycle or throw them away.

The idea is to keep components in use for as long as possible and thus, ROBUS fittings will last longer as a result. This can involve improving the cycle of product development and designing for product integrity. This means designing for long use, extended use, and recovery. Here we have a resilient system that decouples economic activity from the consumption of raw materials which helps to benefit business, people, and the environment.

What is ROBUS doing to tackle the circular economy?

As part of our Environmental, Social Governance (ESG) proposition, we’re taking steps to build circular design into our processes. In becoming a Carbon neutral company in 2022, the mission is to keep moving towards opportunities that allow us to continue creating more sustainable practices and products. In order to reach this feat, we have developed a set of principles to help us to achieve a circular economy.

Our three main principles are:

- Design out waste and pollution (Green/Eco manufacturing methods and component materials)

- Keep products and materials in use (Service and re-manufacturability)

- Regenerate natural systems (Design for sustainable products)

The first steps

Our mission to engage in a circular economy means we now must take necessary steps to ensure that what we’re producing is being made with sustainability in mind. This all starts with design.

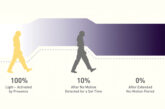

When developing new products or looking at key ranges we can wholly control the design of new luminaries and look at existing key ranges to see what we can change, develop and improve. This can involve making fittings modular so users have the flexibility to swap out components or including switches to fittings to enable them to be dual wattage, CCT selectable or dual test so users can choose one fitting to suit a range of purposes.

As such we need to move away from a reliance on single use products and have a greater emphasis on innovation to keep materials in use and, prolong their lifespan and up cycle. The ROBUS GOLF Modular and LUNATE Quad pro fittings are two examples of fittings which benefit from having modular parts and selectable switches.

As well as this, increasing the longevity of our products by having longer warranties has been a major focus. This will ensure our fittings will have more durable components and the need to replace them will be reduced. For instance, our ROBUS CAPELLA now has a 10-year warranty, our longest warranty yet.

Nothing creates waste like packaging. As we all know, when we buy something, it usually comes wrapped in plastic, bubble wrap or additional film. At ROBUS we have undertaken to tackle this by making our packaging as sustainable as possible. This work has meant reducing all unnecessary plastic, un-recyclable materials and eliminating the need for additional film in our internal packaging.

Over 760 of our product SKUs have seen reduced plastics in their packaging, resulting in reduced plastic coming into the UK by 1 tonne per month and only increasing over time! The results speak for themselves, but we’re not finished there as we’re working on making our outer packaging more sustainable and completely recyclable.

Future plans

Looking at the road ahead, a pivotal step in ensuring we’re engaging in a circular economy that ROBUS is focusing on is standardising batteries, drivers and accessories. This key project will reduce the number of accessories available and will ensure that a small number of drivers, batteries and accessories will work across more of our ranges and will be replaceable instead of the end user having to buy a whole new fitting. This will keep fittings in use longer, and thus contribute to the steps of creating a circular economy.

ROBUS is continuing to look at more ways to keep on the road to creating a circular economy, with plans to investigate other avenues such as ‘selling lighting as a service’. We look forward to seeing what other exciting innovations and plans the circular economy brings.

To explore the full ROBUS product range, click here