Guest columnist Chris Ruddock ponders whether electricians should consider carrying out an insulation test between live conductors to earth for circuits that don’t incorporate a circuit protective conductor (CPC).

Many of you reading this will have encountered a situation where you’ve come across an installation, such as a lighting circuit, that’s been wired in twin PVC cables without an integral CPC included within the circuit.

Indeed, it’s more than likely that you’ve performed a maintenance task on such a circuit by replacing a defective accessory or carried out an EICR on a property that has these circuits in use.

Now, an installation that includes circuits without a CPC wouldn’t normally cause much concern, provided that the accessories, equipment or fittings are suitably insulated to the requirements of Class II. In fact, within guidance materials such as NAPIT Codebreakers and Electrical Safety First’s Best Practice Guide 4 it’s suggested that a ‘C3 Improvement Recommended’ code should be attributed and would not render an ‘Unsatisfactory’ EICR outcome. The installation method used for the wiring has no bearing on this outcome.

All is fine it seems, thanks to the insulated wiring accessories and fittings which eliminate the risk of parts becoming live under fault conditions to that circuit. However, what about a situation whereby a circuit that doesn’t incorporate a CPC comes into contact with extraneous metallic parts, exposed conductive parts of another circuit or the building fabric in general due to damage to that circuit wiring along its route?

A key change was introduced within the 17th Edition Wiring Regulations which saw a re-wording in the way in which insulation testing was carried out. It now requires that insulation tests between live conductors to earth are carried out with the CPC of that circuit connected to the earthing arrangement where previously it allowed the circuit under test to be carried out between conductors with the relevant CPC disconnected.

This updated measure ensured that the circuit under test wasn’t mutually short circuited to earth by another means that otherwise would’ve been missed by disconnection of the CPC during the test procedure.

Given the fact that the circuit doesn’t incorporate a CPC and the wording of the updated method specifically mentions that the CPC should be connected to the earthing arrangements, should a test be carried out on this type of circuit and should a result be obtained to be included in an EICR?

A recent conversation I had with Ryan Dempsey from The Compliance Workbook indicated that 98% of the certificates that had been processed had ‘N/A’ recorded in the corresponding insulation resistance box.

I recently came across an insulation fault on a lighting circuit that originally was wired in twin PVC cable and had been rewired in part with the exception of a switch drop that couldn’t be accessed to be replaced due to a fitted wardrobe in the room above.

Fault finding investigations were carried out to the circuit which specifically concentrated on metallic fittings, metallic wiring accessories and wiring which incorporated a CPC without much success in locating the issue.

As I moved around the installation and started to split the circuit into smaller parts I noticed that the fault cleared as soon as I disconnected the original switch drop wired in twin PVC cable. Further investigations had found that the concealed cable had been damaged in the wall and was shorting to earth via the building fabric and subsequently other parallel paths.

I’d previously overlooked this cable as the cause due to the conductor not incorporating a CPC, but it has since got me thinking that had that been the case for the entire circuit it’s very likely that a test wouldn’t have been undertaken or recorded, and yet this same fault could still exist and not necessarily be discovered.

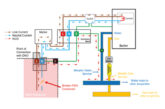

The images (shown below) demonstrate continuity through the lighting circuit CPC and back through the building fabric. The damaged cable is the twin PVC to the light switch which is shorting to the building fabric.

A lot of properties still have circuits that don’t include a CPC, albeit some additional regulations have since been introduced to improve the safety of such installations which may not have been applied retrospectively.

A lot of properties still have circuits that don’t include a CPC, albeit some additional regulations have since been introduced to improve the safety of such installations which may not have been applied retrospectively.

The 17th Edition also saw some changes with regard to 30mA RCD protection of concealed cables within the fabric of the building at less than 50mm and included the requirement of 30mA RCD protection to cables concealed within a partition that is constructed with metallic parts, regardless of depth.

At the time, however, this could be negated by the use of a risk assessment if the installation was deemed under the supervision of a skilled or instructed persons. These requirements were since updated in the Amendment 3 (2015) update which saw the removal of the ‘skilled and instructed persons’ element.

When you check the previously mentioned guides, there’s currently a disparity between Codebreakers, which suggests a concealed cable not RCD protected would warrant a ‘C2 Potentially Dangerous’ and Best Practice Guide 4 which suggests a ‘C3 Improvement Recommended’, so it really does depend on which guidance materials you may be using at the time.

Notice how I refer to them as ‘guidance materials’ as electricians should always use them in such a way, in line with your own engineering skills, judgements and relevant site-specific risk assessments.

A more recent requirement introduced with the 18th Edition Wiring Regulations involved the RCD protection rated at 30mA of lighting circuits within a domestic dwelling. However, this only attracts a ‘C3 Improvement Recommended’ in the guidance materials and only applies to domestic installations.

It’s clear that depending on which type of guidance material you follow it is possible that these particular types of circuits could be deemed ‘safe for continued use’ without any insulation tests being carried out to earthing system to ensure that the integrity of the wiring system is intact and doesn’t present any risk.

So, this poses the question of whether we should be considering this test as a minimum with the result also recorded.

Although some positive changes have taken place in the Wiring Regulations in order to improve safety of the installation, there are many installations still that have no RCD protection whatsoever. Similarly, older installations exist where a 16th Edition compliant consumer unit has been installed without RCD protection to lighting circuits without a CPC.

There’s always been the debate that an installation compliant with an earlier Edition doesn’t necessarily make the installation unsafe and that the requirements should necessarily apply retrospectively given the note provided by the Health & Safety Executive.

Regardless of whether you’re carrying out an EICR or a maintenance repair to an existing circuit, it should be noted on the report or minor works certification that an improvement is recommended with a view to replace the cables.

I understand this isn’t always possible due to client budgets, listed building constraints or disturbance of asbestos etc. but going beyond the requirements and carrying out an insulation test between live conductors and the earthing arrangements demonstrates that you took all reasonable steps to ensure the installation is as safe it can be at the time of the testing.