Steve Humphreys, Technical Commercial Manager at NAPIT, discusses the concept of parasitic capacitance in solar PV installations.

Parasitic capacitance might not be a term most electricians know or have even heard of. It may even drum up images of bugs or other creepy crawlies in our electrical installations. You might be more familiar with capacitance, perhaps from your college days, as the ability of two conductors, separated by an insulating material, to store an electric charge.

The term parasitic capacitance is used to describe any ‘unintended’ or ‘stray’ capacitance in electrical and electronic equipment, conductors and components. It basically arises because any two conductive objects in close proximity have the ability to store an electric charge and create a capacitance.

Now we know what it is, we’ll look at parasitic capacitance in relation to solar PV systems (Fig 1) and in particular solar PV modules.

Parasitic capacitance in solar PV modules

By their design, all solar PV modules will have an electrical capacitance in relation to their environment. This capacitance typically forms between the solar PV modules electrical conductors and surroundings, such as the frame, mounting structure, or the Earth itself.

It’s worth pointing out that this capacitance has no bearing on the functionality or operation of the PV generator, hence the terms ‘unintended’ or ‘unwanted’.

The presence of the capacitance is dependent on the component parts of the solar PV system in relation to the design and installation methods. This will include the physical layout of the component parts of the system, the equipment used and where the equipment has been installed.

Evidence suggests there are several factors that contribute to the presence and level of parasitic capacitance in solar PV systems.

Transformerless inverters

During the normal operation of a solar PV system, the PV modules are connected to the grid supply via the inverter. When transformerless inverters are used they can potentially allow the passage of AC voltage from the installation supply side to the DC side of the solar PV system.

This alternating voltage amplitude appears at the PV module, and as a result, the PV array oscillates with an alternating voltage in relation to its environment.

In single-phase transformerless inverters, up to half the AC voltage is passed on to the PV module i.e. 115 V/50 Hz. In three-phase systems, the pass-through of AC voltage is largely supressed and therefore a much smaller voltage amplitude appears on the DC side of the system.

The issue of having this fluctuating AC voltage on the DC side of the PV system is that it constantly changes the state of charge and therefore the level of parasitic capacitance on the PV array.

Weather impact

In the UK, where high humidity, dew and frequent rain are common, moisture can increase the impact of parasitic capacitance. This is because the moisture can enhance conductive paths and in turn worsen leakage currents. As shown in Fig 2, we have three individual capacitances – C1, C2 and C3.

In wet conditions, the overall capacitance is dominated by the capacitance created by C1 due to water on the glass. Therefore, C2 and C3 do not need to be considered. In dry conditions, where C1 is not applicable, the overall capacitance created by C2 and C3 is likely to be very small and therefore will not affect the solar PV system.

The effect of parasitic capacitance can increase with the size of the solar array, as larger systems have more conductive surfaces.

How does parasitic capacitance affect solar PV systems?

a) Leakage currents

As mentioned earlier, when transformerless inverters are used, they can potentially allow some AC voltage from the installation supply side to the DC side of the solar PV system. This means that where there is a voltage and a resistance, there will be a current. In the solar PV system, the DC side will produce parasitic capacitance leakage currents.

This leakage current has the potential to flow through a person who may be touching the PV array and in contact with any earthed metalwork. Where standard modules with crystalline silicon cells are installed, the total parasitic capacitance could be around 396 nF (nanofarads). This equates to a potential leakage current of 14 mA. Other types of modules, such as thin-film, could have higher leakage currents of around 20 mA.

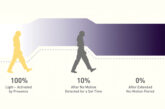

With an AC voltage of up to 115 V and leakage currents reaching potentially dangerous levels, great care is required. If a person touches the array and is in contact with a path to Earth, they will receive an electric shock; it may not be sufficient to cause injury, but might be enough to cause difficulties when working at heights on scaffolding or work platforms, see Fig 3.

b) Inverter efficiency

Parasitic capacitance affects the inverter’s performance, especially when it converts direct current (DC) from the solar panels to alternating current (AC). Inverters can misinterpret leakage currents as faults or disturbances, potentially reducing efficiency and causing operational issues. This could cause residual current devices (RCDs) to operate or the inverter to shut down or run suboptimally.

c) Electromagnetic Interference (EMI)

Parasitic capacitance can cause or worsen electromagnetic interference (EMI) in solar PV systems, which can affect nearby communication devices and systems. In highly dense areas, like cities in the UK, managing EMI is critical to ensure compliance with regulatory standards.

So, what on Earth do we do about it?

To deal with the effects of parasitic capacitance, designers, installers and inspectors can take some reasonable and fundamental steps.

Firstly, compliance with BS 7671 ensures that safe electrical design practices are followed to mitigate these effects. A careful and considered design would involve using high-quality inverters with better filtering capabilities and ensuring proper insulation to reduce the effects of environmental factors such as moisture.

A well thought out and robust risk assessment and method statement (RAMS) will be required to highlight the dangers of parasitic capacitance and safe working procedures. This could include the use of scaffolding, other access equipment and possible insulation of metalwork.

A safe system of work (SSoW) will need to be in place to ensure isolation of the inverter before any maintenance or cleaning of the array takes place. Other steps that can be taken include the option to install a 30 mA RCD on the AC side of the transformerless inverter. This option could cause unwanted tripping and there is also still a risk of electric shock before the RCD operates.

Another option is to Earth the PV modules and array framing system, as shown in Fig 4. This option, at face value, does seem sensible and would divert the voltage to Earth. However, it does create other possible issues around lightning protection, labelling for high protective conductor currents and creating a further shock risk with other extraneous and/or exposed conductive-parts.

Conclusion

With the recent upsurge in renewable technology installations, such as solar PV systems, it’s more important than ever to ensure that designers and installers are fully aware of issues such as parasitic capacitance.

Hopefully, this article has highlighted what parasitic capacitance is, how it affects PV systems and what steps can be taken to mitigate against it.

Visit NAPIT Direct to find out more about the NAPIT Practical Guide: Solar Photovoltaic Systems publication: https://rebrand.ly/SolarPV

For more information on NAPIT Scheme registration, click here

Find more industry technical articles here