Geoff Brittan, NAPIT Technical Officer, discusses selecting the correct Residual Current Devices.

When discussing selectivity of RCDs and how/why we need to achieve this, its important to ascertain what selectivity means with regard to RCDs.

Selectivity is the co-ordination of the operating characteristics of two or more protective devices such that, on the incidence of an overcurrent or residual current, the device intended to operate first does so while the other(s) do not.

Fundamentally, selectivity is the ability of a protective device to operate in preference to other protective devices in series.

Now we have basic understanding of what selectivity is let’s see how we can achieve this.

Where the electrical installation has a TT earthing system, and due to the higher earth fault loop impedance associated with such systems, the installation of sub main distribution circuits would require RCDs for fault protection.

For example, a typical acceptable Ze value for a TT earthing system may be 40 Ω, therefore

equates to 5.75 A of fault current which would be required to operate the protective device. Should such a fault appear on the sub main distribution circuit and if the only provision was for overcurrent protective devices, the example calculation shows there is not enough fault current flowing to earth to operate the overcurrent protective device.

Therefore, unless a low value of Ze can be assured and maintained the requirements of Regulation 411.5.3 for fault protection would have to be met.

Where a requirement for an RCD for the protection of the installation, if a 30 mA RCD is provided the entire installation may be subjected to unwanted tripping.

Therefore, this requires the distribution boards and consumer units to suitably rated RCDs for various parts of the electrical installation. If all the RCDs were rated at 30 mA this would also lead to cases of unwanted tripping where the RCDs has the same tripping residual current levels.

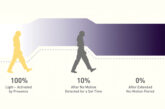

Distribution board RCD protecting sub main circuits can have be S type/time delayed as shown in Fig 1 which act to minimize the risk of danger and inconvenience to the user for operation of downstream RCD units. Time delay RCDs are identified with the following symbol S .

Circuits supplied from the consumer unit downstream would require 30 mA RCD (for additional protection). In this scenario selectivity has been achieved.

Installing RCDs with different mA ratings and or time delayed devices is not a new concept. However, the major change that came in with BS 7671:2018 is the requirement to select the appropriate type of RCD, AC, A, F, or B dependent on the expected load. Correct coordination of Types of RCD is essential when in series, Fig 2 shows the layout of RCD in series.

RCD types

Type AC is used for Resistive Capacitive and Inductive loads generally without any electronic components, e.g. immersion heaters, ovens/hobs with resistive heating elements, electric showers, Halogen lighting.

Type A is used for inverters, multimedia equipment, washing machines, lighting controls, dimmers, home electronic systems, LED drivers, induction hobs and electric vehicle charging points with less than 6 mA of leakage.

Type B is usually used for 3 phase electronic equipment, inverters, UPS, EVCP with more than 6 mA fault current, PV arrays, industrial machines, cranes etc.

Type F is for freqeuncy controlled equipment. This includes some washing machines, dishwashers, and driers containing synchronous motors, some Class 1 power tools and air conditioning speed drives.

You can find more details on NAPIT membership and benefits by clicking here