This article from the experts at NICEIC looks at the requirements of Section 710 of BS 7671 for electrical installations in medical locations, and in particular, considers the requirements for the protection against electric shock in such types of environments.

This article focuses on the requirements for shock protection, including the requirements for the protective measure of Automatic Disconnection of Supply (ADS) that are in addition to the general requirements in Section 411.

The requirements for SELV and PELV and additional protection by supplementary bonding in a medical location will also be considered.

Shock protection

Like many other types of installations considered in Part 7, the protective measures of obstacles and placing out of reach are not permitted in medical locations (710.410.3.5).

Likewise, the protective measures of non-conducting location, earth-free equipotential bonding and electrical separation for more than one item of current-using equipment shall not be used (710.410.3.6).

It should be noted that while medical IT systems offer additional protection against first fault conditions, such use of electrical separation is not intended as the sole means of protection against electric shock (see note to 710.410.3.6). The medical IT system also provides supply reliability.

Additionally, only protection by insulation of live parts, or by the use of Class II equipment are permitted.

Automatic disconnection in case of a fault

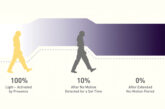

The risks associated with an electric shock due to contact with both AC and DC currents and the subsequent effects on the human body under fault conditions are generally well understood (BS IEC 60479-1). Such that, the average body impedance can be assumed to be around 2 kΩ in a typical environment.

This value will differ between person to person and is influenced by additional factors such as voltage, frequency, skin wetness, physical contact area and duration of current flow.

However, in Groups 1 and 2 medical locations where ME equipment is used and where the natural protection of the human body is expected to be reduced by factors such as cuts or broken skin, this impedance value tends to be much lower and is assumed to be 1 kΩ (BS EN 60601-1), further increasing the vulnerability of patients to the risks of electric shock.

Additionally, the patient’s defensive capability may also have been reduced by the effects of medication or anaesthesia.

For this reason, regulation 710.411.3.2.5 requires a reduction in the conventional maximum touch voltage from 50 V, to 25 V AC and 60 V DC between simultaneously accessible exposed-conductive-parts and/or extraneous-conductive-parts in Group 1 and 2 locations when supplied from TN, TT and IT systems. This may be achieved by the provision of supplementary bonding, which is considered later in the article.

Additional protection by RCDs

In a TN system, RCDs having the characteristics specified in regulation 415.1.1 shall be used to provide additional protection for final circuits in:

- Group 1 medical locations, with a rated current up to and including 32 A, and

- Group 2 medical locations, except for those circuits supplied by a medical IT system as specified in 710.411.6.

However, RCDs may also be used on final circuits rated above 32 A employed in Group 1 locations (710.411.4).

Where medical locations of a Group 1 and 2 classification are supplied from a TT system earthing arrangement, regulations 710.411.5 and 710.415.1 require that RCDs shall be used as the protective devices for final circuits, except where these circuits are supplied from an IT system specified in regulation 710.411.6.

Where RCDs are required in Group 1 and 2 medical locations, and depending on the fault characteristics, only Type A in accordance with BS EN 61008 or BS EN 61009, or Type B or Type F to BS EN 62423 shall be used. The use of Type AC RCDs is not permitted (710.531.3).

Extra-low voltage provided by SELV or PELV

Where SELV and/or PELV is used within such locations, the nominal voltage supplying current-using equipment should not exceed 25 V AC rms or 60 V ripple-free DC.

Additionally, protection by basic insulation of live parts, or alternatively protection by barriers or enclosures as required by regulation 416.1 and 416.2 respectively shall be provided (710.414.1).

When using SELV and/or PELV circuits in Group 1 and 2 medical locations, a source as described in regulation 414.3(iv) should not be used (710.414.3).

Furthermore, where PELV is used in a Group 2 location, for example to supply the theatre luminaires, any exposed-conductive-parts of such equipment should be connected to the circuit protective conductor (710.414.4.1).

Additional protection by supplementary protective equipotential bonding

Regulation 710.415.2.1 requires that supplementary protective equipotential bonding is installed in Group 1 and 2 medical locations.

The purpose of such protective bonding is to provide additional protection against electric shock by limiting the magnitude of touch voltages during a fault.

The supplementary bonding conductors shall be connected to the Equipotential Bonding Busbar (EBB) to facilitate the equalisation of potential differences between those specific parts as listed in indents (i) to (v) in regulation 710.415.2.1 that are located, or that may be moved into, the patient environment.

For this reason, supplementary bonding connection points shall be made available for ME equipment used in Group 2 locations, and similarly, should also be considered for Group 1 medical locations.

The number of connection points required shall be determined by the designer in consultation with the end user. However, Note 1 to regulation 710.415.2.1 recommends that:

- In Group 1 medical locations – a minimum of one supplementary bonding connection per patient location is provided, and

- In Group 2 medical locations – a minimum of four supplementary bonding connection points but not less than 25% of the total number of individual medical IT socket-outlets is provided per patient location.

Protective conductors in Group 1 and 2 medical locations must be correctly sized and arranged so that their resistance does not exceed 0.2 Ω (710.415.2.2).

The resistance between the protective conductors and the earth terminal of any socket-outlet (or fixed equipment) and any exposed-conductive-part and/or extraneous-conductive-part must be such that the voltages of 25 V AC or 60 V DC, given in regulation 710.411.3.2.5 are not exceeded.

In addition, the cross-sectional area (csa) of a supplementary bonding conductor must be at least that required by regulation Group 544.2.

Section 710 recognises that, in some cases, supplementary bonding conductors installed in loops can lead to electromagnetic interference (EMI) due to the presence of circulating currents and may affect some types of sensitive electrical ME equipment (710.444).

To mitigate any potential issues in Group 1 and 2 medical locations, Note 2 to regulation 710.415.2.3 recommends that radial wiring patterns are used to avoid such ‘earth loops’ that may intensify such electromagnetic interference.

Equipotential bonding busbar (EBB)

All supplementary bonding conductors should be connected individually to the EBB (see Fig 2), which in addition, must be made readily accessible and located in or near each medical location in which it serves (see Fig 1).

The EBB should be connected to the means of earthing for the installation with a protective conductor having a cross-sectional area (csa) greater than or equal to the largest csa of any conductor connected to the EBB. All connections shall be clearly visible, identified and so arranged to enable bonding conductors to be individually disconnected (710.415.2.3).

When installing the EBB, consideration should be given to meeting the local infection prevention and control requirements for such types of location. The EBB should be contained in a suitable enclosure and not be installed in a ceiling void where, for example, during an inspection, falling debris due to the removal of a ceiling tile may likely increase infection risk (710.415.2.3).

Summary

This article has focused on the requirements for shock protection in Group 1 and 2 medical locations and considered the necessary precautions to prevent an increased risk of electric shock to vulnerable patients within such types of environments.

We would like to acknowledge and thank Brandon Medical for providing some of the images used within this article.

Get more details about NICEIC registration here

Find more industry technical articles here