NAPIT’s Chief Technical Officer, Frank Bertie, discusses the process of functional testing and what is required.

Functional testing is one of the sequence of tests for initial verification and included for periodic inspection and testing.

BS 7671:2018 requirements under Regulation 643.10 for functional testing is often misunderstood in that it only covers the simple operation of checking that devices are able to be switched on and off. In reality, the operation known as functional switching can be described as normal control and operation for electrical equipment.

Requirements for functional testing

Although not specifically mentioned as functional testing in Part 1 of BS 7671:2018, it mentions operation of devices for a variety of purposes such as emergency control, disconnecting devices, switches and isolation.

Initial verification under Regulation 134.2.1 places a duty on the skilled person to ensure that the requirements for BS 7671 are met and appropriate certification is issued. Further details are within Chapter 64 and Chapter 65.

Definition

Part 2 provides definitions within BS 7671. Although not a definitive list, we do have functional switching which states “An operation intended to switch ‘on’ or ‘off’ or vary the supply of electrical energy to all or part of an installation for normal operating purposes.”

Although not fully explaining functional testing, as part of the requirements for Regulation 643.10, it does indicate that the switching is part of the testing regime to ensure for initial verification that the switches and controls that are part of the installation and operate correctly under normal conditions.

Maintainability

Chapter 34 requires that the person responsible for the operation and/or maintenance should be consulted to ensure that an assessment is carried out on the frequency and quality of such maintenance.

This requirement has the effect on the designer/installer/inspector to ensure that the appropriate selection, installation and verification is carried out at each step to consider the effect on the expected life of the electrical installation. Failure to carry this out can lead to a shortened lifespan for part, or the whole, of the electrical installation.

Functional switching

Chapter 46 covers functional switching, which includes isolation and switching and for any such devices, the requirements of Chapter 53 that apply to the functioning of the device have to be met.

Functional switching as described under Regulation 463.1.1, can be provided for sections of the installation that require to be operated separately from other parts of the installation. Such devices don’t need to switch off all live conductors, although neutral conductors can’t be used in a single-pole switching device.

Regulation 463.1.3 has provisions for each item of equipment and shall be controlled by an appropriate functional switching device, although this also includes a single device to control several items of equipment.

Functional switching devices can be a manual or automatic operation and can control the current-using equipment without necessarily opening and closing the contacts. This places a restriction on certain switching operations, such as the use of semiconductor devices. While they’re suitable for functional switching, they can’t be used for isolation purposes as described in Regulation 537.2.2.

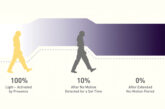

Table 1 and Fig 1 show examples of the types of functional switching devices.

Protection, isolation, switching, control and monitoring

Chapter 46 provides details of the requirements for isolation and switching and Chapter 53 covers further requirements for protection, isolation, switching, control and monitoring. Between both of the chapters they go into detail of the nature of the functional switching.

To meet the requirements for the various functions Table 537.4 in BS 7671 lists the range of devices, the product standards they have to comply with, and which operation they can be used for.

Table 2 shows the difference between protective devices, a circuit-breaker and a fuse, where the circuit-breaker satisfies all of the requirements of Table 537.4 including functional switching and a fuse which can only be used for isolation purposes.

For socket-outlets with different current ratings, although all can be used for isolation, only those not exceeding 32 A can be used for functional switching and not for emergency switching.

Inspection and testing

Within Chapter 46, Regulation 461.1 has the provision that for each type of device they have to meet the intended function(s) where they’re provided for isolation or switching, in compliance with Chapter 53. To that effect functional switching is included within the inspection schedules and checklists listed in Part 6 and in Appendix 6 of BS 7671.

Regulation 643.8 covers additional protection, this provides the requirement for confirming the effectiveness of the RCD using a suitable test instrument which includes functional operation. This has various aspects where the correct disconnection of the RCD is in the permitted time and that the operation provides isolation of all live conductors, including the neutral where required.

The final operation of the RCD test button is another functional test that is required to be carried out during initial or periodic inspection and testing.

Although a fairly new development, Arc Fault Detection Devices (AFDDs) can have a manual test button which would also have to be verified under functional testing. Verifying the presence, condition and correct operation in accordance with BS 7671 for the devices such as switchgear, switch fuses, circuit-breakers, RCDs and isolators, is part of the requirements of Regulation 643.10.

Although a fairly new development, Arc Fault Detection Devices (AFDDs) can have a manual test button which would also have to be verified under functional testing. Verifying the presence, condition and correct operation in accordance with BS 7671 for the devices such as switchgear, switch fuses, circuit-breakers, RCDs and isolators, is part of the requirements of Regulation 643.10.

Remember, when completing the inspection schedule for initial or periodic inspection and testing, we’re confirming that each of the devices are performing to the requirements of BS 7671.

Conclusion

It’s essential when carrying out initial verification or periodic inspection and testing, which includes functional testing, that we have an understanding of the purpose and application of all devices installed within any electrical installation. This includes the correct classification of operation for the devices.

NAPIT has several publications that cover the requirements of inspection and testing; these are available in both printed and electronic format via the online NAPIT Direct store.

Get more information on NAPIT scheme registration by clicking here